Description

Wrap & Seal Pipe Burst Tape is a waterproof pipe repair tape made from self-fusing silicone which seals live leaks on pipes made from copper, PVC plastic, steel, malleable iron, and many other materials.

The tape stretches by three times its length and once applied, it fuses to form a solid rubber band which exerts maximum pressure over the hole or crack in the pipe. Using multiple tapes creates a repair which is pressure resistant up to 30bar and Wrap & Seal is temperature resistant up to 200°C.

Wrap & Seal is suitable for fixing leaks in applications ranging from small domestic plumbing problems through to large scale industrial pipe repairs. Because it is effective on live leaks, using Wrap & Seal avoids costly and disruptive shutdowns of systems.

The versatility of the product makes it suitable for wrapping car exhausts, hoses and other types of pipes. Wrap & Seal is WRAS approved, meaning that it can be used safely with drinking water.

Wrap & Seal can also be used as an electrical insulation tape. For more details, please go to the Electrical Repair Tab.

Wrap & Seal Pipe Burst Tape details – how to repair a leaking pipe with waterproof tape

Wrap & Seal is easy to use and depending on the size and pressure of the pipe, repairs can be carried out in under 15 minutes by simply following the instructions provided.

The repair begins by anchoring the waterproof tape next to the leak area. Using the centre line as a guide, you stretch the tape to its maximum and wrap it around the pipe until it runs out. The unique tapered profile of Wrap & Seal stops water from tracking underneath the tape, completely sealing the leak.

One Wrap & Seal Tape will typically hold 5bar pressure. Further pressure resistance can be built up by using additional tapes. If you are undertaking a high pressure repair, then please use the Repair Calculator tab to determine the number of tapes required for your repair.

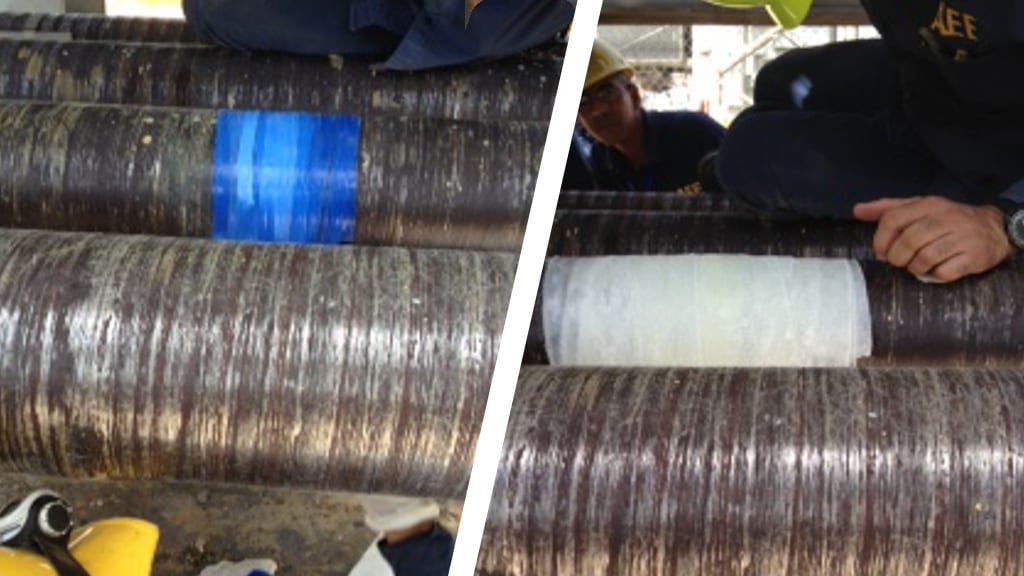

Repairs made with Wrap & Seal should be reinforced by applying a SylWrap Pipe Repair Bandage over the Pipe Burst Tape. The Bandage offers a rock hard, impact resistant layer of protection which turns the repair permanent.

Both Wrap & Seal and SylWrap Bandages are available in the Universal Pipe Repair Kit which contains all the equipment needed for fixing live leaks in an emergency. For a kit that allows for multiple pipe repairs to be carried out, then please see the Contractor Case.

Benefits of Wrap & Seal Pipe Burst Tape

- Tape is extra thick and stretches by 300% for a high pressure seal

- Easy to use – just follow the instructions provided to tape the leaking pipe

- Repairs can be carried out to pipes without the need to turn off flow

- Tape can be easily removed if necessary and leaves no residue

Applications

- Copper pipe repair, PVC plastic pipe repair, steel pipe repair, iron pipe repair, GRP pipe repair, ceramic pipe repair, concrete pipe repair, lead pipe repair, rubber pipe repair

- Domestic plumbing repairs and large scale industrial applications

- WRAS approved for repairs to pipes carrying drinking water

- Repairs to non-plumbing pipes, such as car exhausts and hoses