Description

Liquid Metal is a metal-filled, epoxy compound which is brush applied to provide a protective coating to steel, other metals and most plastics from chemical attacks and corrosion.

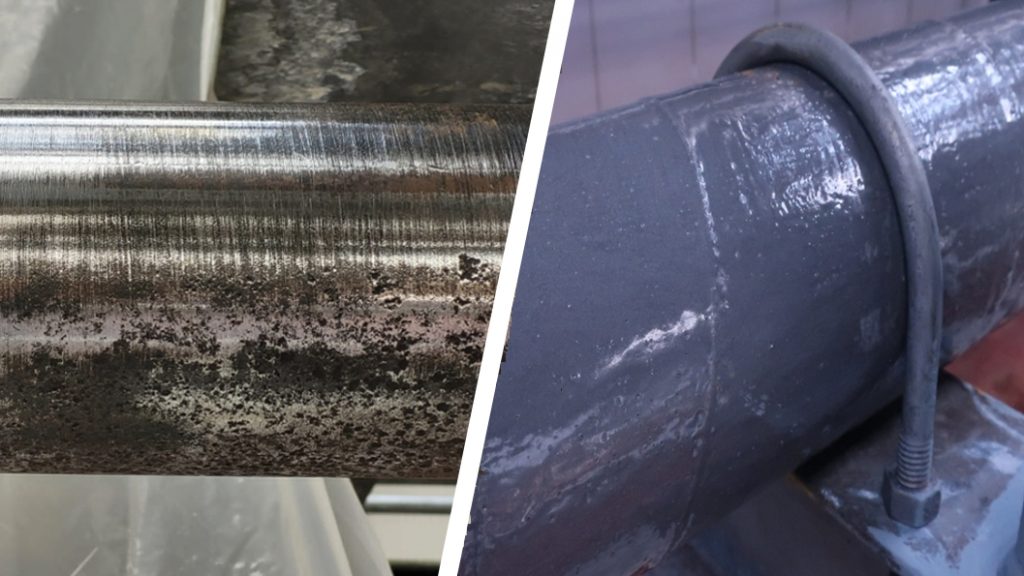

When coated onto pipes and machinery, it sets to provide a smooth, metallic, hard-wearing outer surface which acts as a shield against external corrosion and chemicals. Liquid Metal also protects from internal corrosion by creating an impermeable membrane around pipework and systems, capable of withstanding future breaches from inside.

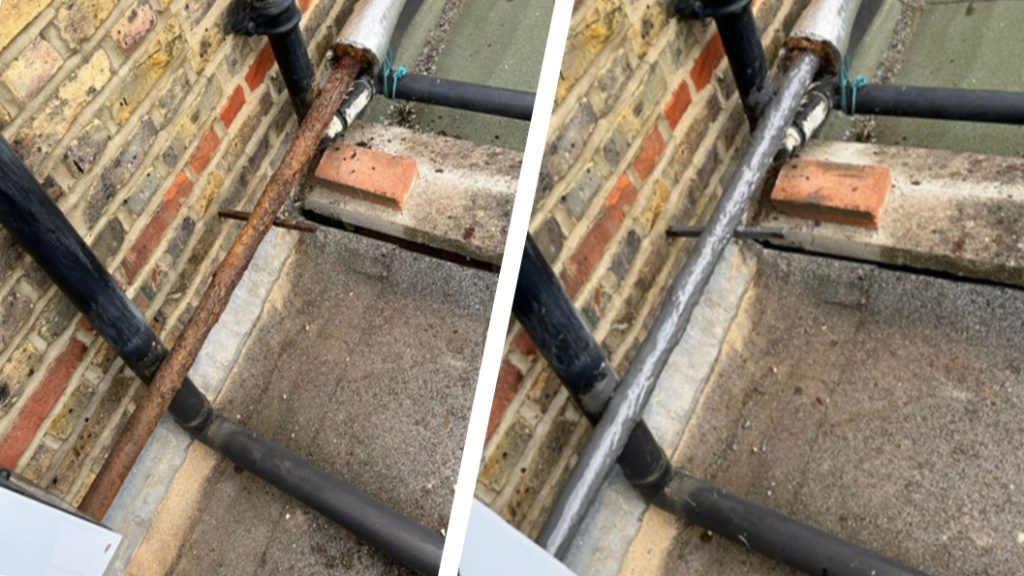

Coating a pipe with Liquid Metal Epoxy increases the effectiveness of the protective shell provided by a SylWrap Composite Wrap. The epoxy coating maximises surface contact area between the pipe and the composite wrap and increases adhesions.

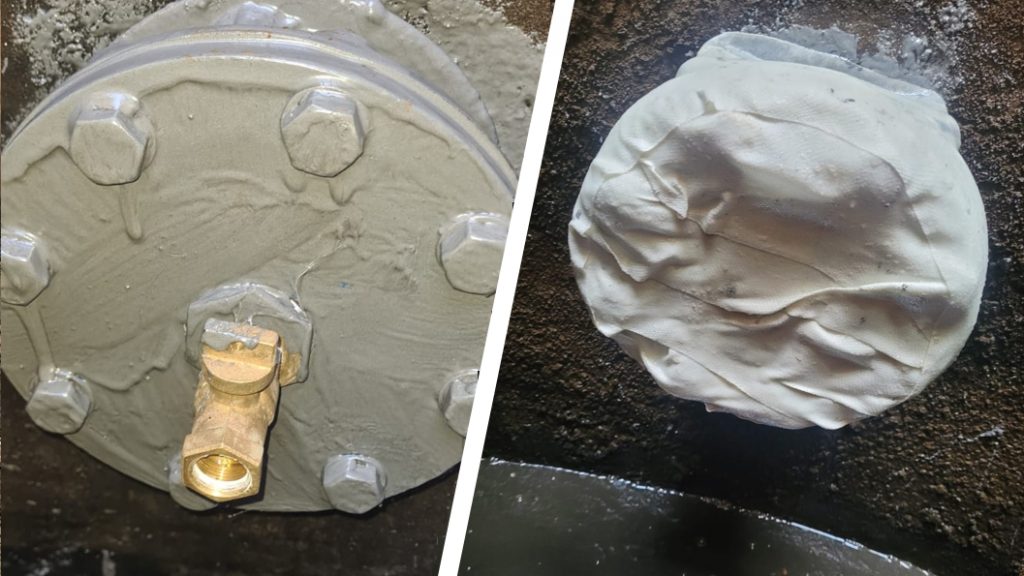

Liquid Metal can also be used as an adhesive for re-gritting floors and other surfaces, pouring into moulds to create metal casts, and for the maintenance and repair of tanks, pumps, valves, flanges, engines, and impellers.

With a 90 minute gel time, Liquid Metal can be mixed in larger quantities without the worry that it will cure before completion. Sylmasta recommend the use of Liquid Metal to clients in warmer climates because of this longer work time.

How to use Liquid Metal as an epoxy coating for repair and maintenance

Before applying Liquid Metal, surfaces should be free of paint, rust and grime before being roughened up through either grit blasting or grinding with a coarse wheel or abrasive disk pad. Full instructions detailing the preparation process can be found on the Technical Data Sheet and are provided with the product.

Liquid Metal should be applied as soon as the preparation procedure is completed. To ease the mixing process, the resin container has enough room to dispense all the hardener into the resin, so that it can be applied with a brush straight from the container.

The epoxy is brush applied and each coating should be 0.5-1.00mm thick. To ensure a pinhole-free coating, at least two coats are needed. The re-coating time between coats is approximately 5-8 hours after applying. A full functional cure is achieved 24 hours after the final coat.

When overwrapping with a SylWrap HD Pipe Repair Bandage or another composite repair wrap in pipe repair applications, the wrap should be applied once the layer of Liquid Metal has gelled but remains tacky.

The light consistency of Liquid Metal makes it easy to mix and apply with little sag. It is virtually odourless, with no unpleasant smell, can be easily machined and is temperature resistant to 150°C.

For protecting pipework and machinery subjected to extreme temperatures in excess of 150°C, please see Titanium Supergrade HT Epoxy Paste.

Liquid Metal is not effective underwater. For corrosion protection of pipes in marine and underwater environments, Sylmasta recommend the use of SylWrap CR Corrosion Protection Wrap. SylWrap CR is a specialist composite repair wrap infused with additional corrosion inhibitors which is applied directly to pipes underwater.

To determine the quantity of Liquid Metal needed for a specific pipe repair application, please go to the Repair Calculator Tab and enter your repair data.

Benefits of Liquid Metal

- Easily mixed and applied – just paint onto a surface using a brush

- Increases protection against corrosion and chemicals

- Longer working time allows for complex jobs to be carried out

- Can be easily machined

Applications

- Protection of metal and plastic pipes from chemical attack and external corrosion

- Forming an impermeable membrane to prevent breaches caused by internal corrosion

- Maximising surface contact to composite repair wrap

- Repair and maintenance of pumps, impellers, flanges, water box ends, valves, metal casting, pipe elbows, tanks

- Can be poured into a mould to create metal casts

- Bonding grit to floors and machinery to provide non-slip and non-stick surfaces

- Increases corrosion resistance of metalwork when painted on as a protective coating

- Chocking, filling and levelling machinery and equipment